Description

This project involves the construction of a network of production facilities for the utilization of the contents of ash dumps of coal thermal power plants (TPP), and through their deep processing, obtaining a product that meets the requirements of environmental and technological supervision, high quality, cost-effective.

Production

The project of Construction of the complex provides for the production of:

- Mineral additives – 160 thousand tons/year,

- Iron – 15 tons/year,

- Carbon – 45 t/year,

- Alumina – 80 thousand tons/year,

- Cement – 320 thousand tons/year.

Mineral additives from technogenic raw materials: ash, ground slag, silica fume and others have different mineralogical composition and dispersion, which determine the effectiveness of their use in cements and concretes.

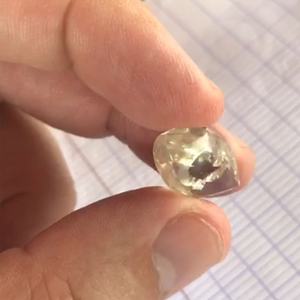

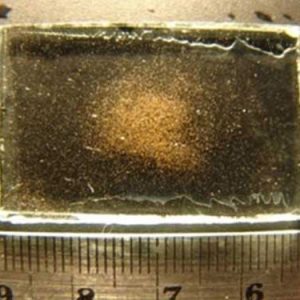

Thermal power plant ash produced by burning of pulverized coal from their mineral part, which contains clay substance, quartz, and carbonate rocks. Depending on the furnace temperature (1200-1600 C) and particle size, the mineral part of the coal either melts completely or is melted from the surface. During cooling, the vitreous phase of the material is formed. Ash particles are deposited in electric filters and removed dry (fly ash or dry ash removal) or wet (water removal ash). Fly ash has higher properties and is widely used in cement and concrete technology.

The chemical composition of ash is characterized by a content of 35-60% SiO2 , 15-35% A12O3, 1-20% Fe2O3, 1-30% Cao and a small amount of MgO, SO3, alkalis and other compounds. The ratio of the components of the ash determines its activity and binding properties.

Ashes chemical and mineralogical composition are largely identical to natural mineral raw materials. Their use in industry, construction industry and agriculture is one of the strategic ways to solve the environmental problem in the TPP area. Slags and ashes have a good prospect for their wide use for the purpose of resource saving, that is the solution of the economic problems connected with preservation of natural resources of nonferrous, rare metals and other materials.

Recycling of Ash and Slag is a promising direction for the development of small and medium-sized businesses.

Application in Construction

The use of additives in cement mortar allows to give the material additional properties necessary in a situation specified by the technological features of the installation and operating conditions of the facility. The use of additives is quite wide and “closes” quite a large part of the technological needs of builders.

As a result of our technological process, the mineral additive for cement mortars helps not only to improve the quality of construction products (reduced thermal conductivity of concrete, reduced weight of buildings and structures), but also to reduce its cost by 30%.

This mineral Supplement developed and approved technical conditions TU 5745-001-87669128-2011. The most profitable complex use of lightweight concrete. When the weight of concrete is reduced by 10%, the cost of construction is reduced by 3%. The average cost reduction in the application of ash in light concrete is 5%, and in some areas 30%. Developed, implemented, or developed about 20 technologies for the production of lightweight concrete with the additive.

The main consumers of products on the market are industry, construction industry (concrete and cement plants) and agriculture.

To take part in the Project, please contact us >>>

Receive ProValue Updates

Be aware of new supply offers and requests from our customers.