Description

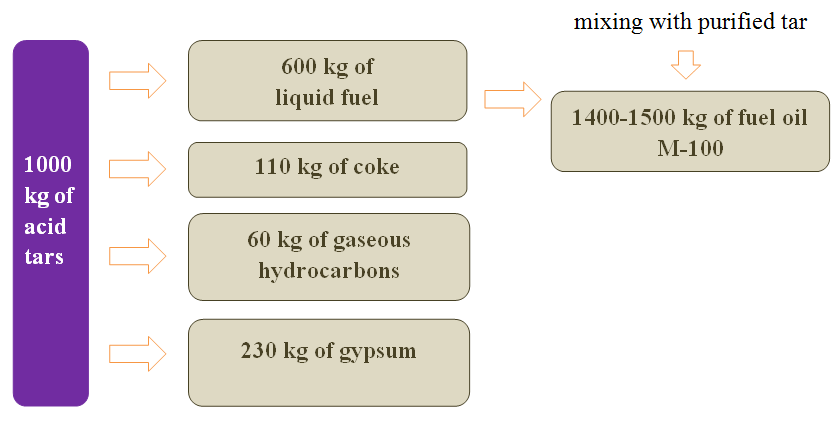

The project involves the construction of production facilities for deep processing of waste oil fields, 800 thousand tons of acid tar and other oil sludge. The end result of the production cycle is the production of construction products and materials, gypsum, coke and furnace fuel M-100. Recultivated land is supposed to be used for low-rise housing construction.

The project will be implemented on the territory of 60 thousand square meters adjacent to tar ponds. Installation of the equipment at this site will allow you to completely get rid of the cost of transporting sludge.

Will also purchased property in the second land plot with the area of 13 thousand square meters, on which is located the plant for the blending of lubricating oils.

For Investors

We invite investors to take part in this project. At the moment, all agreements have been reached with the administration of the region, and the project is fully ready for launch. If you have any questions, please contact us.

Ecological situation

According to most expert estimates, as a result of human economic activity in the world annually lost from 120 to 200 million tons of produced liquid hydrocarbons. In Russia, this figure is 15-25 million tons. At the same time, the rate of processing of waste formed as a result of the loss of valuable hydrocarbon raw materials, significantly lags behind the rate of their accumulation.

For almost a century, the main reason for consumer attitudes to the environment lay in two factors:

- low cost of oil on the background of growing oil production;

- lack of technologies for economically profitable processing of oil waste.

Only at the turn of the XX and XXI centuries the configuration of both factors began to change: the price of hydrocarbons fluctuated from a record high to a record low level, and technologies in the field of processing of oily waste made a big leap.

In a number of areas there are storage ponds filled with acid tars – waste from the activities of oil Refineries. The neighborhood of these ponds with the territory of the village is a disaster for its inhabitants.

Subject to reclamation, this area will again be suitable for economic use.

Technology of processing of oil sludge

It is assumed to use a variety of technologies for processing oily waste, with the exception of thermal neutralization, namely:

- Three-phase centrifugation and three-phase separation.

- Physico-chemical cleaning using acoustic cavitation.

- Bioremediation in closed loop in simulatanously mode.

- Ultrasonic systems of destruction and stabilization of heavy hydrocarbons.

Processed products

Processing of oil sludge, will allow to adjust release of the following production:

- Fuel Oil M-100

- Heating oil

- Fraction 360-420

- Bitumen

- Mastics

- Gypsum

- Petroleum coke

Economic performance

The project is not only clearly profitable, but also has a positive impact on the environment, improving the living conditions of the local population.

Funding required: 289 928 000 RUB

Commissioning: up to 2 months

Monthly profit: 93 096 000 RUB

Net profit for 5 years: 6 910 072 000 RUB

To take part in the Project, please contact us >>>

Receive ProValue Updates

Be aware of new supply offers and requests from our customers.